We just got back from Apimondia in Copenhagen—three days of talking with beekeepers from 47 countries, all describing the same frustrating pattern.

"Strong colonies all summer. Harvest day: almost nothing."

Whether it was a commercial operator in Australia, a hobbyist in Montana, or a researcher in Egypt—same story, different accent. Good management, disappointing results.

The conversations kept circling back to one question: Why do identical practices produce completely different outcomes?

This month's deep dive answers that question with something most beekeeping advice skips: actual physics. Because your October harvest isn't mysterious. It's mathematics.

And once you understand the energy economics at play, next season starts looking very different.

— The Primal Bee Team

Why your honey harvest disappoints (and the physics that explains it)

Standing in your pantry this October, counting fifteen jars when you expected fifty, isn't mysterious. It's mathematics.

All summer, those hives looked textbook-perfect. June brought solid brood patterns. July saw populations explode. August meant constant foraging traffic. You timed everything right, controlled mites meticulously, followed every protocol. Then harvest day revealed the truth: almost nothing.

Meanwhile your neighbor three miles away, following similar management, pulled sixty pounds per hive. Same weather. Same flowers. Completely different results.

Most beekeeping advice offers vague explanations—"bad nectar flow," "weird season," "sometimes they just don't make honey." Those aren't answers. Those are shrugs.

Here's what research reveals actually happened: your bees spent everything they collected just surviving in that box.

Not because you failed as a beekeeper. Because the energy economics don't work out.

Stabentheiner's 2024 landmark study finally quantified the annual cost of raising brood: 96 pounds of honey. That's roughly half of what an average colony brings in during a decent season. Why so expensive? Because larvae need exactly 98.8°F and pupae need exactly 96.8°F—not approximately, not close enough. Those exact temperatures.

Drop it two degrees: weird wings, shorter lifespans, learning problems. Drop it four degrees: high pupal mortality. Drop it eight degrees: almost total developmental failure.

After that 96-pound non-negotiable biological cost, colonies pay for winter stores (60-70 lbs in cold climates), emergency reserves, and daily operations. Surplus honey—what you extract—only happens after all bills are paid.

October's empty supers aren't failure. They're physics revealing itself.

The frustrating part? Colonies look totally healthy while running energy deficits. You see brood frames, foragers working, busy entrance activity. What you miss: every calorie goes straight to overhead—keeping lights on instead of building savings.

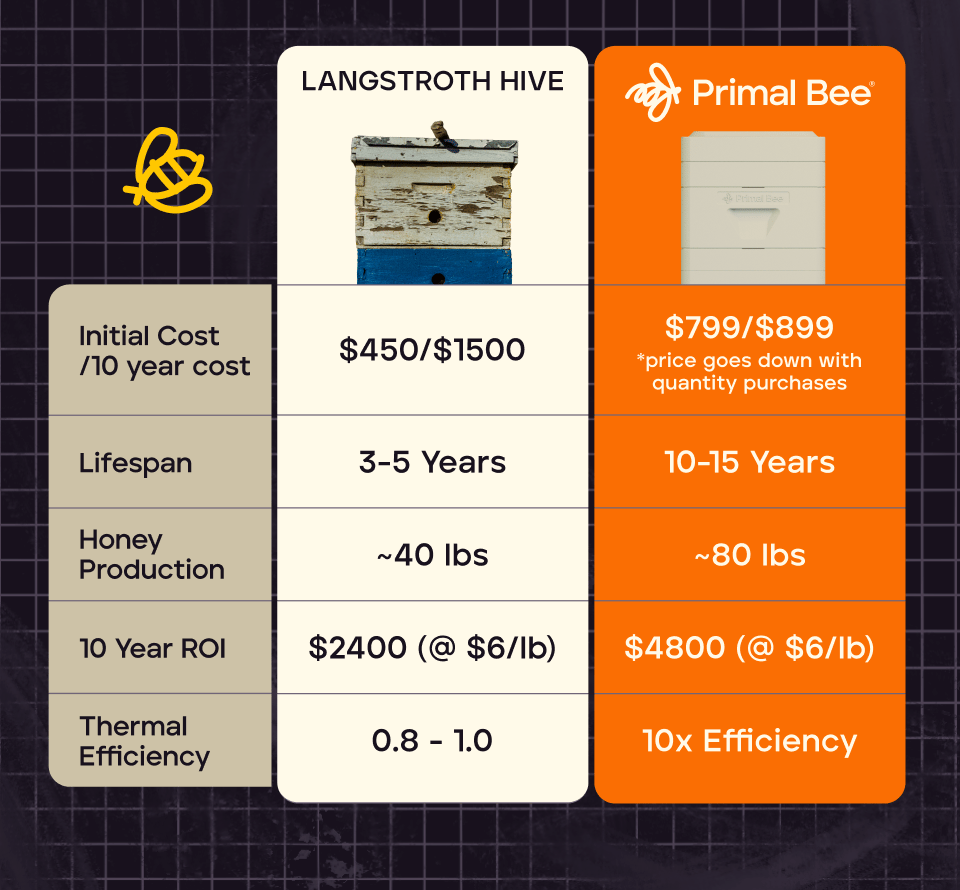

Next season, those same bees in those same boxes will produce the same disappointing results. The 96-pound brood cost applies next year. The 26% additional energy burden in wooden hives happens again next spring. You can't change the biology. You can't negotiate with physics.

But you can change the foundation.

Right now, while empty jars sit in your pantry and the evidence is fresh—this is when different decisions get made for next year. Not in March when packages arrive. Not in May when flows start. Now.

Because next October, you'll be standing in your pantry again. The only question is whether you're counting fifteen jars or fifty.

"My biggest harvest disappointment this year was _______."

Reply with your answer—we'll share the most common responses in our next issue and address them with practical solutions.

📈 5,000 registered beekeepers in FL today? Double what it was a decade ago.

🐝 Virtual beekeeping? Taiwan just made learning hive work sting-free with MR headsets.

🎓 Six lectures, one field day, $80 — get from novice to checking hives with confidence.

🐝 He’s a full-time student and a 50-hive beekeeper — school + bees = life’s buzzy balance.

One advantage of our hive design that doesn't get talked about enough: when disease strikes, you don't have to burn everything.

Wooden hives exposed to American Foulbrood (AFB)? They must be destroyed. The spores survive in the wood fibers, remaining infectious for decades.

Primal Bee hives? They can be thoroughly disinfected and safely reused.

The Complete Cleaning Protocol

Following National Bee Unit guidelines for plastic/polystyrene equipment:

Step 1: Pre-cleaning

Place hive components in a chest freezer (-20°C) for at least 48 hours to kill wax moth and other pests

Scrape thoroughly to remove all wax, propolis, and organic material

Burn all scraped debris

Pay special attention to corners and crevices

Step 2: Disinfection with Bleach

Dilute household bleach to 0.5% sodium hypochlorite in cool water

Soak each surface for 30 minutes (for large components, treat one wall at a time)

Research shows this concentration kills AFB spores and other bacteria

Step 3: Rinse and Dry

Rinse thoroughly with hot water to remove all bleach residue

Dry outside in sunlight

Safety notes: Wear protective clothing, gloves, and eye protection. Use bleach only in well-ventilated areas. Never mix bleach with other cleaning products.

Why This Matters

Equipment you can disinfect and reuse:

Reduces replacement costs after disease outbreaks

Maintains biosecurity without destroying functional equipment

Provides peace of mind knowing you have options beyond burning everything

Wooden beekeeping has one answer to AFB: destruction. Modern materials give you another option.

Want the full technical details? Read the complete National Bee Unit guidance: Disinfecting a Hive After Disease

Until Next Time

Winter planning season is here—the quiet months when next year's results get decided.

If this October's harvest told you something needs to change, now's the time to act. Not in March when packages arrive. Not in May when flows start. Now.

The math that didn't work this year won't magically fix itself next season.

We're here if you want to talk through what different could look like. Reply to this email or visit [primalbee.com] to explore how thermal efficiency changes the foundation.

Stay warm out there,

The Primal Bee Team